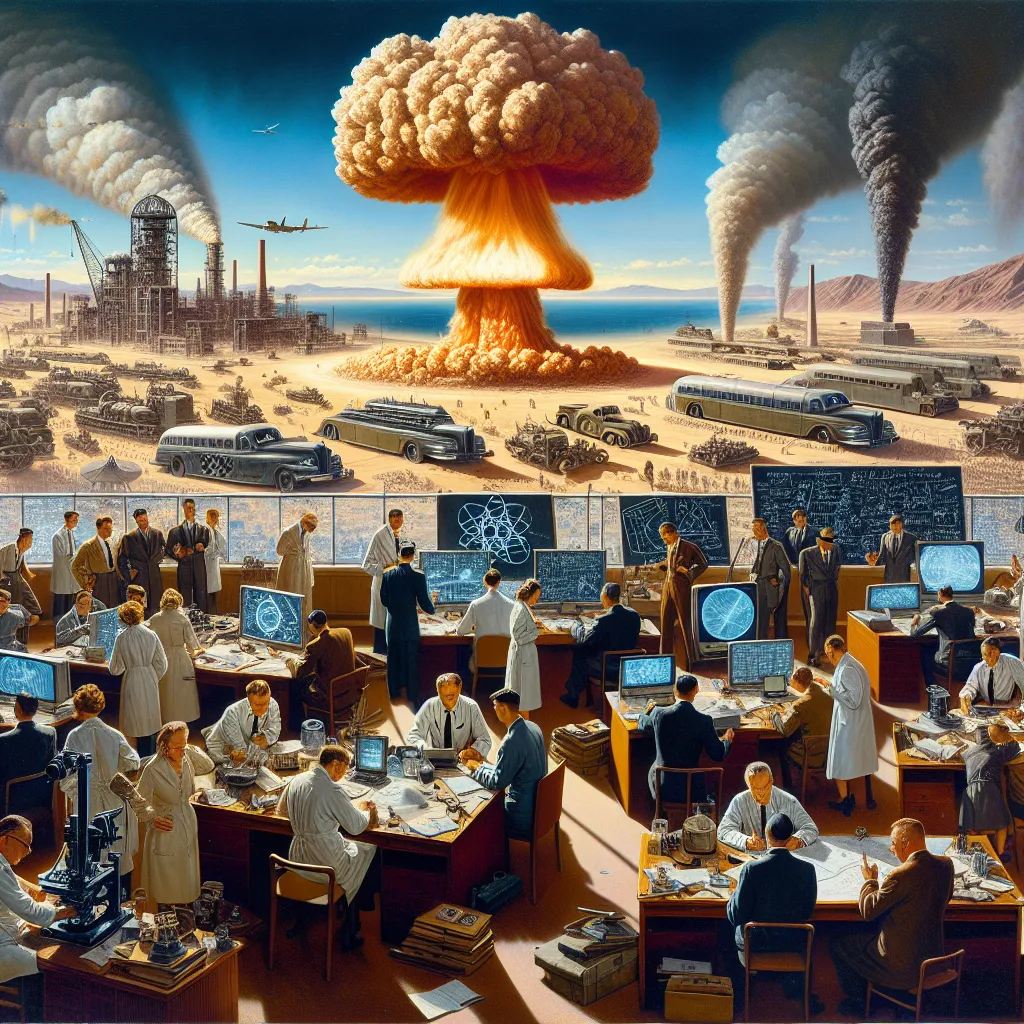

Paul and Andy are tackling one of the most challenging and expensive cleanup jobs in the world. They are responsible for the decommissioning of the Dungeoness nuclear power station in Britain’s wild East. Their task involves removing over 500 tons of spent fuel housed in 54,000 fuel rods. The challenge? The fuel is radioactive and needs to be handled with extreme caution to avoid radiation sickness. The rods must stay underwater, or they could overheat and possibly catch fire.

The first goal is to extract the fuel rods from the reactor. Each reactor contains about 27,000 fuel rods, each weighing around 10 kilos of radioactive uranium. These rods were initially used to produce heat, which generated steam, ultimately converting it to electricity. Now, after years of service, they are hot, radioactive, and toxic. The fuel rods need to be moved to a specially designed facility for cooling and long-term storage.

Andy and Paul seem calm, but they are well aware of the danger. They use an electronic personal dose meter to measure their radiation exposure. Protective suits and boots ensure that radioactive dust doesn’t escape from the contamination-controlled area. Their day involves navigating the “dirty side,” where they are about to open up the reactor, shut down since 2006.

The reactor, once Britain’s longest-running nuclear power station, contains about 2,100 tons of uranium. Andy and Paul have to lift a two-ton slab of concrete, the last shield before reaching the reactor. They won’t handle the fuel directly; instead, a robot crane will pull out the rods and drop them into a water-filled storage pond. These ponds serve to cool the rods and protect workers from radiation.

When the reactor was active, the area was extremely hot. Now, conditions are much more manageable. The fuel rods are extracted using a remote-controlled grab, and everything is monitored by video to ensure safety. The rods are then moved underwater to the storage skips, where 20 tons of water keep them cool and radiation levels in check.

The next phase involves packaging the fuel rods into flasks designed to withstand severe accidents. Each flask weighs about 50 tons, made of thick steel, and is watertight and airtight. One famous test involved crashing a train into a flask at over 80 mph—the flask survived unscathed.

After sealing and testing the flask, it’s transported by truck and train nearly 400 miles for reprocessing and storage. The journey is managed by experienced drivers who perform meticulous checks to ensure everything is safe and secure. Finally, the flask reaches its destination, where the fuel will either be reused or stored in deep underground facilities, potentially for thousands of years.

As bad as it may sound, eventually, the remaining structures of the reactor will be sealed for 50 years before demolition begins. The last brick won’t be removed until 2098, marking the end of one of the most challenging cleanup operations in history.